Drawn sheet glass, as the name implies, is a sheet of glass that is drawn directly from the furnace.

The method was developed in the pursuit of a way of producing larger sheets of glass for use in windows. Prior to machine-drawing, the size of cylinder- and crown glass was limited by the capacity of the glassblower’s lungs.

Machine drawn sheet glass was the result of fierce competition between some of the world’s leading window glass factories such as Pilkington in England, Saint-Gobain in France and several glass factories in Pittsburgh in the USA. Victory eventually came to Saint-Gobain in 1915, when they revolutionised the window glass market with a machine that could draw sheets of glass three metres in width in virtually unlimited lengths. The method was patented in 1904 by the Belgian Emile Fourcault.

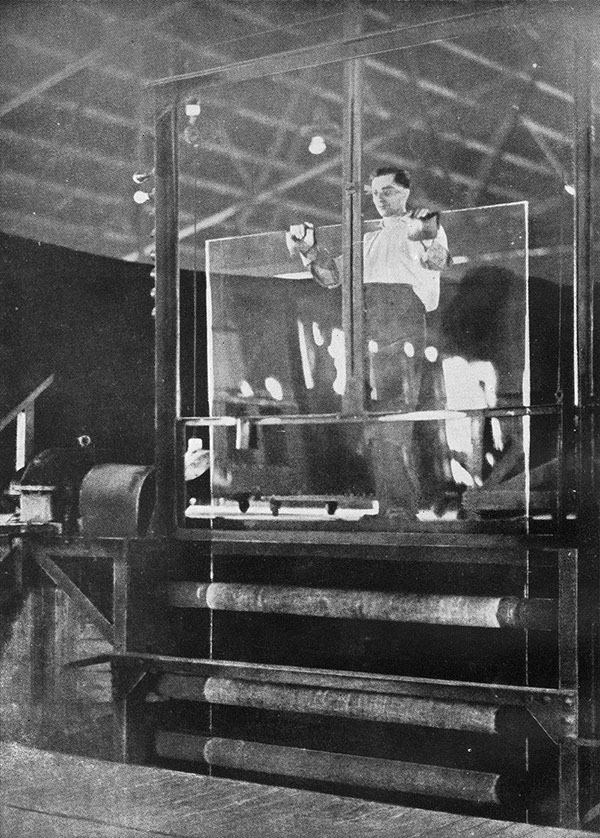

In principle, the production of drawn sheet glass is a very simple affair. The molten glass is drawn directly from the furnace through a series of steel rollers that squeeze the glass into the required thickness. On its way up through the rollers the glass cools down and at the top of the machine sheets of glass can be cut off in manageable lengths that are later cut into panes.